Advanced Production Scheduling: How AI Enhances Decision-Making in Manufacturing Industry

Advanced Production Scheduling: How AI Enhances Decision-Making in Manufacturing Industry

AI in manufacturing services leads to effective planning and proper scheduling resulting in improved financial gains for manufacturers. Using a production scheduler application in any industry helps to utilize the available resources to a maximum extent. AI-powered algorithms in such an application perform multiple tasks such as automatic creation of plans with real-time monitoring. Eventually, this automated approach will ensure that the decision-making quality of manufacturers is improved. Making adjustments on the go to the production timelines based upon the resource availability guarantees increased productivity. Top-notch quality products are developed with the integration of the Advanced Production Scheduling (APS) application with any ERP tool like SAP or Oracle.

Three Decisive Stages of Advanced Production Scheduling

Today’s manufacturers rely a lot on APS for making crucial decisions at every stage of production right from planning capacity based on demand to adhering to quality standards. Having a detailed understanding of each stage helps any decision-maker get equipped about the renewed production scheduling process.

1. Demand-based Capacity Planning

Precise demand forecasting results in numerous benefits such as resource allocation and utilization in a timely fashion.

2. Sequential Tasking in Production

Accomplishing tasks based on priority will improve overall efficiency backed by a proper production workflow.

3. Resource Optimization for Improved Productivity

Powerful AI algorithms give crucial data insights about the resources to be allocated for a specific task.

How Manufacturers Reap Huge Benefits Industry-wise by Implementing APS?

Introducing AI to the production process not only speeds up the tasks but also improves the quality of the output produced. Additionally, it helps in saving time and efforts taken to develop a product. A manufacturer gets to know which professional to be deployed for a certain task by mapping the qualifications, experience, specialization, and certification in real time. This has become possible in no time because of the data insights made available by the APS instantly.

Accurate estimation of a product development based on the resources, time, and demand emphasizes on the fact that the tasks can be completed much faster than anticipated.

1. APS for Supply Chain Management in Manufacturing

How to determine when the resources have to be augmented or curtailed? Is there a substantial way to increase production volumes dynamically based on the demand? What is the extent to which the deliveries can be sped up? Any supply chain can be properly maintained only when the demand is met on time. Ultimately, this results in manufacturers scheduling the tasks with utmost efficiency within minutes.

2. APS for Quality Medicine Production in Healthcare

Exact predictions can be made in the healthcare segment related to drugs. For instance, it is possible to estimate which medication to be produced apart from determining the desired quantity along with the composition. This dynamic feature proves to be handy in those instances where prescription-based drugs are required urgently. It all depends upon the successful decisions taken by the concerned manufacturer based on the real-time data available from the APS tool.

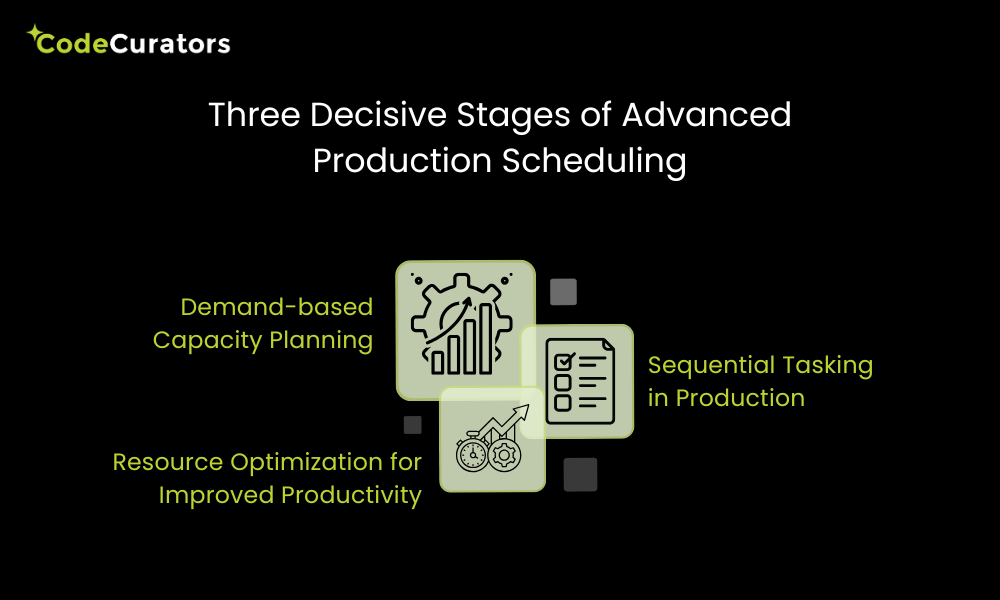

What Difference can APS make for Manufacturers?

Manufacturers, especially those working in larger production units, are burdened with multiple tasks that take place simultaneously. This often results in unnecessary collisions resulting in a chaotic situation leaving a manufacturer in a confused state.

By making use of APS, it is possible to take better decisions by:

1. Updating Schedule

Making changes to a complex schedule on a day-to-day basis can actually disrupt the original schedule. However, the introduction of AI to the existing production process will wipe out such a situation by automatic scheduling of tasks based on priority.

2. Sequencing Tasks

Imagine a task that has to be finished months before is not yet untouched because of other tasks. With AI, it is possible to decide which task has to be completed first because of the sequential arrangement of all the tasks.

3. Generating Schedule

Much like updating a schedule, it is possible to generate a new schedule for a specific task with new start and end dates. This works best in those scenarios wherein a manufacturer believes that a particular task is not important at that time.

4. Setting up constraints

The power of APS is undermined if constraints are not set for schedules in any project. The most appreciable part is that the level-based constraints can be set ensuring faster completion and delivery of the project. All a manufacturer has to do in such a situation is to set up a priority for tasks in the pipeline. It all belongs to the process of making adjustments to the sequence for a smoother flow ultimately.

5. Working with Scenarios

A unique feature of the production scheduling is that it allows dynamic changes to the scenarios that are immediately updated and made visible to all the stakeholders of the project. Some common actions that can be performed with scenarios are creating, duplicating, monitoring, updating, and deleting. The advantage of having scenarios in the production system is that any changes made to the flow are immediately available for everyone ensuring that the project is completed faster.

Use Case 1: Manufacturing – APS to Resolve Complex Problems in a Production Unit

Advanced Production Scheduling can be streamlined with AI to run a production unit successfully.

1. Description

A reputed company’s production unit was experiencing performance issues with lowered productivity due to complex workflows that are becoming highly unmanageable. The manufacturers were experiencing huge demands constantly that were not met as there was no coordination among the employees.

With the enablement of APS in the system, there were significant changes experienced by the stakeholders right from the onset.

2. Increased Productivity

As transparency has been brought in regarding the process flows and insights available to the manufacturers readily, the tasks are being completed faster than before. Any change or update in the scenario is immediately updated to everyone involved leading to communication lags. The time taken to deliver the project has been drastically reduced as a result.

3. Reduced Inventory

Every task in the system is precisely tracked with the performance being monitored regularly. It resulted in careful planning of resources bringing down the costs involved in the purchase of raw materials. APS has helped in keeping track of the available stocks and syncing the same with the project. Regular updates about the raw materials were being posted to display the current status.

4. Enhanced Support

Accurate scheduling of the project has allowed manufacturers to be more liable during and even after the project has been delivered. On-time delivery of the project has been possible because of proper planning throughout. Detailed reports about the project’s delivery lifts the morale of manufacturers enabling them to handle such projects in future with renewed confidence.

Use Case 2: Logistics – APS Improves the Service Quality with Reduced Delivery Times

How a logistics firm overcame delivery challenges with APS?

1. Description

A logistics firm was facing severe problems because of the lack of a proper prediction system in place regarding the orders placed and received. Also, the planning process is affected due to the non-availability of service due to traffic or manpower.

The introduction of APS into the system has changed the entire situation ensuring that the firm runs profitably.

2. Web-based Order Registration

Customers were encouraged to register their orders online so that the process of tracking them can be done with even more consistency and accuracy. Firstly, the resources were being allocated based on the number of orders placed. Secondly, an improved logistical planning has resulted with the ready availability of the orders received based on the date and traffic.

3. Predictive Analytics

AI-based demand predictions based on the real-time data available has improved the quality of goods delivered significantly. Latest traffic updates and weather reports were included with the data available as part of predictive analytics. The probability factor too has helped in predicting the orders which has resulted in balancing the production loads.

4. Capacity Maximization

Planning the capacity based on the demand was a major concern before. However, with the data made available from AI algorithms, it has been possible for the logistics firm to increase the capacity whenever needed. Monitoring the current order progress has made it easier for planning and delivering future orders.

5. Real-time Feedback

Improving the order delivery in terms of speed and accuracy has been possible because of the APS. With the availability of regular stats about the logistic planning, the sequence of deliveries too was been improved. Without an AI-based production scheduling system in place, it would not have been possible to run business for the logistics firm.

Conclusion

APS models based on AI tools will become the norm in the near future. Perhaps, almost every organization is looking forward to inducting such models into their production systems considering the huge benefits involved. As every stage is monitored, the quality of data made available will only further improve the process. Enhanced collaboration among departments will result in better quality control and improved business management. Integrating APS with ERPs from Microsoft will take the decision-making capability of manufacturers to the next level.

Interested in streamlining your production process? Learn how you can deploy a suitable APS model in your system leading to improved performance and increased quality. With the production scheduling process to going the AI way, it is possible for companies to experience faster growth in near future.