How to Get Started with AI in Manufacturing: A Step-by-Step Guide

How to Get Started with AI in Manufacturing: A Step-by-Step Guide

If you are in the manufacturing industry, you are well aware of the buzz AI in manufacturing has created and probably looking for ways to get along with the trend.

Let’s be honest: on a busy day when you are caught up between meetings, production targets, supply chain disruptions, and equipment breakdowns, finding time and budget to explore something is difficult.

At Codecurators, we understand the complexities your manufacturing team faces and create a practical solution for your work floor that reduces downtime, improves quality output, and lets your team make better decisions faster. We understand it could be a little daunting, but AI solutions for manufacturing can help the plant managers, operations leads, small and mid-sized manufacturers, and everyone else who is trying to find a way to stay competitive in the market.

Here’s a quick guide to help you leverage technology for better productivity and better business operations.

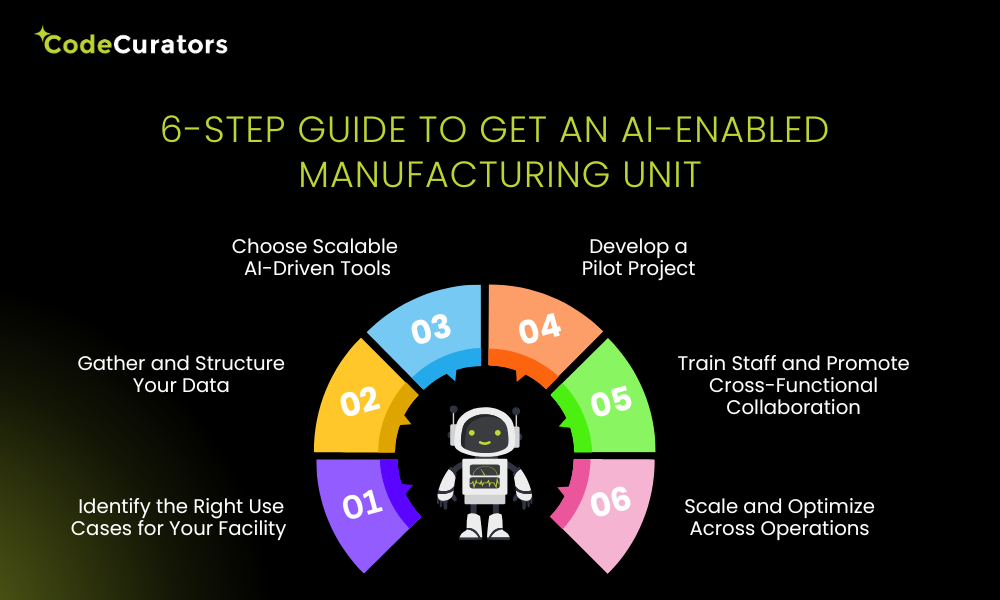

6-Step guide to get an AI-Enabled manufacturing unit

Step 1: Identify the right use cases for your facility

Before you prepare yourself to dive into the complex world of AI solutions, the smarter thing to do is to figure out the areas where advanced solutions can make a difference in your business operations.

Time and cost savings

Start by analyzing the time-consuming or costly pain points in your factory. Major problems could be machines breaking down without warning, defects slipping through quality checks, and you struggling to align production with fluctuations in demand. These are a few points where AI can serve as a great help.

Example: BMW employs AI-automated robots in their manufacturing units. These robots are specially designed to manage the welding and painting works on the planet. After some time, the company found that AI helped it increase its production by 20%. – Source.

Predictive maintenance

You can use real-time data to flag potential equipment failures even before they occur, thus saving you from any loss during downtime. Computer vision systems can analyze and detect products much faster than humans and detect problems more accurately, thus reducing errors and waste. With smart predictive tools, you can fine-tune your inventory levels based on customer behavior and seasonal trends.

As you align some smart tools with your current challenges, you’re not just chasing the trends but getting solutions to your problems. The goal is to use AI to find use cases where it improves efficiency, helps your team make smarter calls, and boosts your functioning.

Step 2: Gather and structure your data

The effectiveness of AI is reliant on the quality of the data that drives AI, and in manufacturing, that quality data exists on your shop floor.

Collect accurate data

In almost every manufacturing process, machines and sensors provide useful data through continuous collection and transmission; however, unless you have established a method of capturing that data, it remains untapped. You have to start by collecting accurate, real-time data from its equipment.

Use sensors and IoT technology

Smart sensors and IoT devices, and you are capable of tracking every aspect of machines, from temperatures, vibration, and run-time throughput, which you can visualize and take action on. This includes monitoring dashboards that can use real-time data or use the data and set it to feed into real-time monitoring dashboards, which makes the data usable and gives everyone visibility, allowing team members to prioritize issues and plan. But data collection is only the first step.

Data management tools

For systems to work for AI, the data needs to be processed to have structure and organization. The software is called data management tools when they standardize, clean, and label data; this helps AI models understand patterns and provide insights of value to organizations, such as predicting an asset to failure or optimizing the production schedule or dynamic resource allocation.

Some popular AI-enabled data management tools

1. Google Cloud

2. Microsoft Azure

3. AWS (Amazon Web Services)

4. SAP Data Intelligence

5. IBM Watson Analytics

Simply put, the clean and organized data you prepare is considered fuel, which will power your productive AI system.

Step 3: Choose scalable AI-driven tools

After you’ve sorted out your appropriate use cases and have a steady data stream coming in, next comes the task of choosing AI-driven tools that are built for your organization. Not just the impressive PILOT or marketing-driven AI tools, but the ones that suit your size, purpose, operational goals, and current processes.

Trust AI-powered platforms

Scalability will be a key consideration. You may want to consider tools that can be implemented into your operation as modular or independent deployments, meaning you can start with a more focused tool (visual inspection module, predictive maintenance software, etc.) and start to scale when you feel you need it or it has created value. In this category would be AI-powered platforms, real-time automation software, and digital twin technology, just to name a few. Many of these tools have been built to scale with you and offer limited upgrades and add-ons without forcing you to rip and replace your entire existing system.

Integrate easily

You’ve probably invested a lot in existing legacy machinery, ERP systems, or SCADA-based platforms, and probably don’t want to have your teams learn new AI platforms from scratch. The best AI tools are designed to integrate with what you already have, whether through APIs, edge devices, or middleware. Seamless integration gives your teams a familiar platform, and they won’t have to completely reinvent the wheel.

Intuitive dashboard

Tools with intuitive dashboards, guided onboarding, and limited IT overhead will lead to adoption by your team while reducing hesitance to implement change. To summarize, choose tools that fit your needs today but can be used tomorrow. The goal is to create an AI ecosystem that also evolves with you, without reinventing everything or needing a massive investment for every scale opportunity. The smart, modular decisions you make today lead to a flexible, future-ready operation that delivers value over time.

Step 4: Develop a pilot project

Here’s a suggestion: Instead of deploying AI broadly throughout your facility, you should pilot a smaller project. It’s safe and intelligent to evaluate what works and what doesn’t work while not turning your entire operation upside down.

Select one challenge to focus on. You might have challenges with quality on a particular line, or you have one piece of equipment that is always down for maintenance. You know what to improve upon, but evaluate for a set time, pick a few goals, and pick your KPIs. Now, for the actual tools, this is where the project takes off.

Edge AI devices (working on the floor), cloud-based analysis of the actual site metrics, or an easy plug-and-play vision system for defect detection will see the test through quickly and smartly. These are set up for fast feedback, so you’ll know what is working and what small tweaks might make things better. The learning aspect is to learn fast and adapt quickly and keep your team informed along the way.

Step 5: Train staff and promote cross-functional collaboration

Incorporating the best AI tools will only get you so far; it is essential to prioritize the people behind them. That is why at Code Curators, we offer training for your people and encourage collaboration as important as the technology.

We start by reskilling workers to instill confidence in the technology they will be leveraging to enhance everyday tasks. You do not need to turn an entire workforce into data scientists, but you will want your operators, technicians, and supervisors to be able to read dashboards, interpret alerts, and take action based on AI-driven insights.

We get IT and production technical teams engaged early. AI does not work in a silo–it impacts software, machines, and workflows.

Finally, the more engaged you get your staff, the less friction you have when it comes to adoption. People value what they build. With the right technology and the right people, the AI tool will go from an outsider in the shop to a partner in the shop that runs your factory, day in and day out.

Step 6: Scale and optimize across operations

So your pilot worked—great! Now it’s time to think bigger. Next up is rolling out what you learned across the rest of your business.

Start with what worked. Was your AI tool a hit in quality control? Try applying it to a similar process elsewhere. Tools with a centralized platform shine here—they let you manage different AI applications like predictive maintenance, real-time monitoring, and prescriptive analytics all in one place. That makes scaling way less crazy.

As you grow, you need to track the impact. Optimization tools can help you measure ROI, spot bottlenecks, and figure out what’s driving performance. You’re not just growing for the sake of it—you’re growing in the right direction.

And here’s the thing about AI: it’s not a “set it and forget it” kind of deal. The best results come when you treat it as an ongoing process. Keep an eye on the data, tweak your processes, and stay open to change.

Conclusion and next steps

Don’t be overwhelmed by AI in manufacturing. Just take it one step at a time—pick the right use case, get your data in order, choose scalable tools, run a pilot, train your team, and then scale smartly. The long-term benefits of AI are hard to ignore. From reducing downtime and improving quality to making faster data-driven decisions, the payoff is huge when done right.

If you’re ready to get started, start small. Pick one challenge, try out a simple AI-powered tool, and see what kind of results you get. Use those insights to build momentum and grow from there.

And remember, there’s no one-size-fits-all solution. The best tools are the ones that fit your operation’s size, goals, and pace of change. Start where you are, build as you go, and let AI help you move your manufacturing operation forward with confidence.

Ready to explore what AI can do for your business? Find a tool that works for you, use it, and then allow the data to drive your next steps. The future of manufacturing is not coming; it’s already here. Now is your time to take the first step. Contact us to learn more and take your next step with confidence.