What are the Top Examples, Use Cases, And Benefits of AI in Manufacturing

Manufacturing is undergoing a transformation because to artificial intelligence, which improves productivity, accuracy, and sustainability. Predictive maintenance, quality assurance, automation, and more intelligent decision-making are some of the key advantages. Manufacturers must integrate AI to stay competitive in a changing market because it boosts productivity, lowers costs, and improves worker safety despite obstacles including high costs and data dependency.

What are the Top Examples, Use Cases, And Benefits of AI in Manufacturing

Manufacturing is undergoing a transformation because to artificial intelligence, which improves productivity, accuracy, and sustainability. Predictive maintenance, quality assurance, automation, and more intelligent decision-making are some of the key advantages. Manufacturers must integrate AI to stay competitive in a changing market because it boosts productivity, lowers costs, and improves worker safety despite obstacles including high costs and data dependency.

The rapid evolution of technology has ushered in a new era for industries worldwide, with artificial intelligence in manufacturing leading the charge. These revolutions are revolutionizing the methods of product development and delivery and go to unheard-of levels of automation, precision and added value. Manufacturers are now integrating AI to solve problems, to foresee a breakdown, and enhance workflows.

From advanced robots to predictive maintenance, artificial intelligence-powered solutions are transforming established procedures. Examining useful applications, prominent use cases, and the many advantages AI presents to firms negotiating a more competitive market, this article explores how this technology is changing the manufacturing sector.

How does AI enhance efficiency in manufacturing?

Organization and productivity have always been the key elements in the structure of manufacturing, and AI cannot be further helpful in the process. AI harnesses significant amounts of data from machine constructs, the production line and the marketplace to discover more efficient ways of functioning.

The global AI in manufacturing market size was valued at USD 8.14 billion in 2019 and is projected to reach USD 695.16 billion by 2032. One main area where the use of AI increases productivity is in the area of predictive maintenance.

Originally, the manufacturers used only a mechanical type of preventive or corrective maintenance, which means that they could only guess when their products were going to fail or could plan for periodic maintenance checks in a timetable that might be unconnected with the actual need.

AI-based systems, on the other hand, provide constant supervision through sensor and analytics and can predict when perhaps a part in the machinery might fail. This means that damages can be effected and sorted early enough without much time being lost to equipment breakdowns hence improving on its durability.

Automation by AI Robotics also adds to efficiency through removing hardworking and repetitive tasks. For example, robots that are incorporated with AI can either build, bond, or even package products with high efficiency and accuracy.

Collaborative robots, or cobots,are designed for joint operation with employees; the concept significantly applies human creativity with robotic precision. This synergy makes it possible for manufacturers to improve productivity by enhancing quality production.

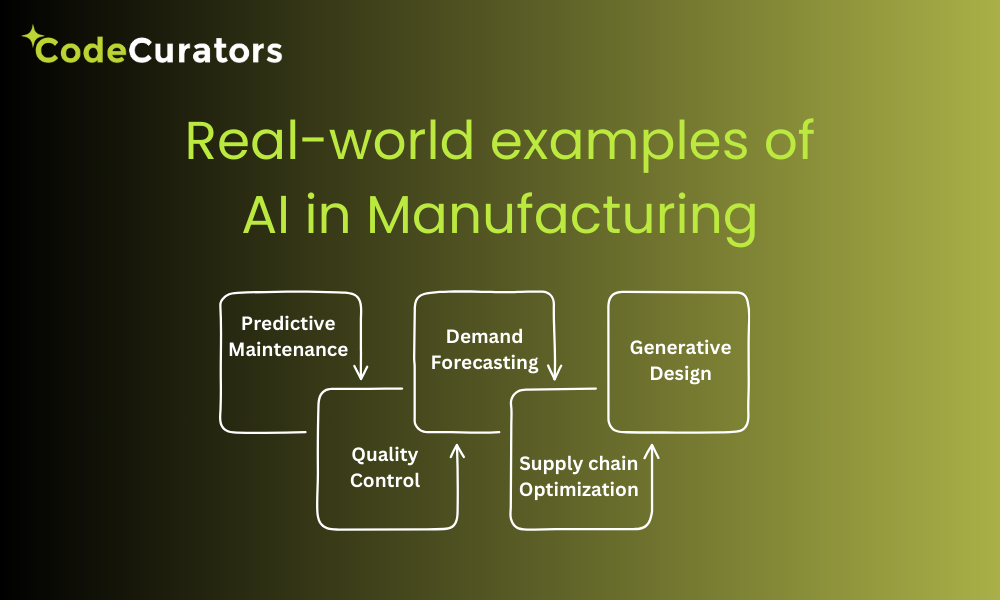

What are real-world examples of AI in manufacturing?

AI is already showing positive returns within diverse manufacturing industries. Here are some noteworthy examples:

1. Predictive maintenance

Companies like GE and Siemens are pioneers in leveraging AI for predictive maintenance. In this way, with the help of data from sensors, their AI systems can predict device failures in advance, days or even weeks. It reduces incidences of a halt on production and allows what has been planned to go on as calendar and time dictate.

2. Quality control

Nowadays, firms like BMW have implemented the use of AI-based computer vision in the production processes. These systems use some form of image recognition to pick up on abnormalities such as scratches, dents, or seemingly off alignments in most instances within milliseconds. This not only improves the quality of the product but also does away with wastages and rework charges.

3. Demand forecasting

AI is useful in demand forecasts, the foundations of which are currently being set. For instance, Unilever recently revealed it uses Artificial Intelligence Algorithms to forecast customers’ demand of their products based on previous sales records, conditions and trends. This makes it possible to achieve the right stock, to accommodate the right stock without some vices such as overstock or out of stock problems.

4. Supply chain optimization

Amazon’s supply chain success is a testament to the power of AI. The mechanisms of algorithms based on machine learning allow the e-commerce giant to enhance the control over stock, storage facilities, and delivery. This level of optimization helps to minimize operational cost whilst at the same time ensuring short order turnaround.

5. Generative design

Many aerospace companies including Airbus are now using AI in generative design. Specific requirements, including weight, strength and necessity of materials, are entered by engineers and multiple design solutions are provided by an AI. Researchers defined that an AI-optimized design is much lighter yet stronger and cheaper as compared to original designs.

How does AI improve quality and precision?

AI’s assure high quality, and its precision makes the difference for the manufacturer. The previous tools used in quality control were based on the ability of the human eye to inspect the products, this was disadvantageous because the human eye may miss some defects due to tiredness or even carelessness.

AI however is superior when it comes to checking for discrepancies compared to human beings in this case. Within the manufacturing industry, most respondents (59 percent) state that quality control is the most important use case for artificial intelligence.

Examples of AI-driven quality enhancement:

- Automotive industry: Tesla has implemented AI surveillance on welds and assemblies that need accuracy as small as micrometers. This gives both structural and product qualities and hence the company’s reputation.

- Pharmaceutical manufacturing: It keeps necessary checks upon the medicine production and management of dosages of various medicines so there can be no compromise on the issues of safety and effectiveness.

Apart from the elimination of defective and, therefore, non-saleable products, AI contributes effectively to the achievement of sustainable objectives by cutting unnecessary use of raw materials and energy. For instance, AI control can allow a flexible management of material consumption, guaranteeing that every amount is used optimally without any compromise of quality.

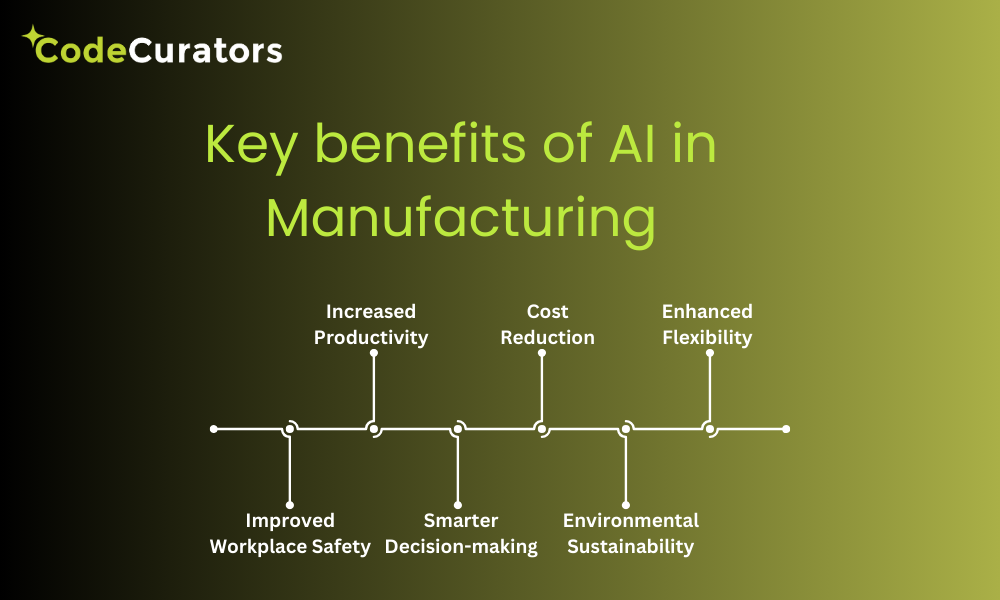

What are the key benefits of AI in manufacturing?

1. Increased productivity

AI automates repetitive procedures and thereby increases the manufacturing rate among the manufacturers. Through continuous functioning without being weary, the use of robots under the AI operations’ umbrella can help increase throughput.

2. Cost reduction

Predictive maintenance minimizes that time as well as the frequency of repairs. AI is projected to increase productivity by 40% or more in the manufacturing industry by 2035. Moreover, AI helps to save material consumption and energy as well these strategies also help in reducing expenses.

3. Enhanced flexibility

Production lines powered by artificial intelligence are incredibly flexible so the same line can produce different variations of a product and changes in market trends can easily be handled as well.

4. Improved workplace safety

AI relieves human workers of dangerous tasks that they used to perform. Hazardous work can be done by robots, and AI systems track the state of the workplace concerning safety in real-time.

5. Smarter decision-making

Real-time analytics and predictive insights let companies decide with knowledge. AI ensures optimal efficiency by helping to maximize everything from inventory levels to manufacturing schedules.

6. Environmental sustainability

Manufacturing sustainability goals are met because AI helps cut down on energy consumption and wastage. For example, skills can be used in the identification of chances of reclaiming raw materials or reducing energy use in the production process.

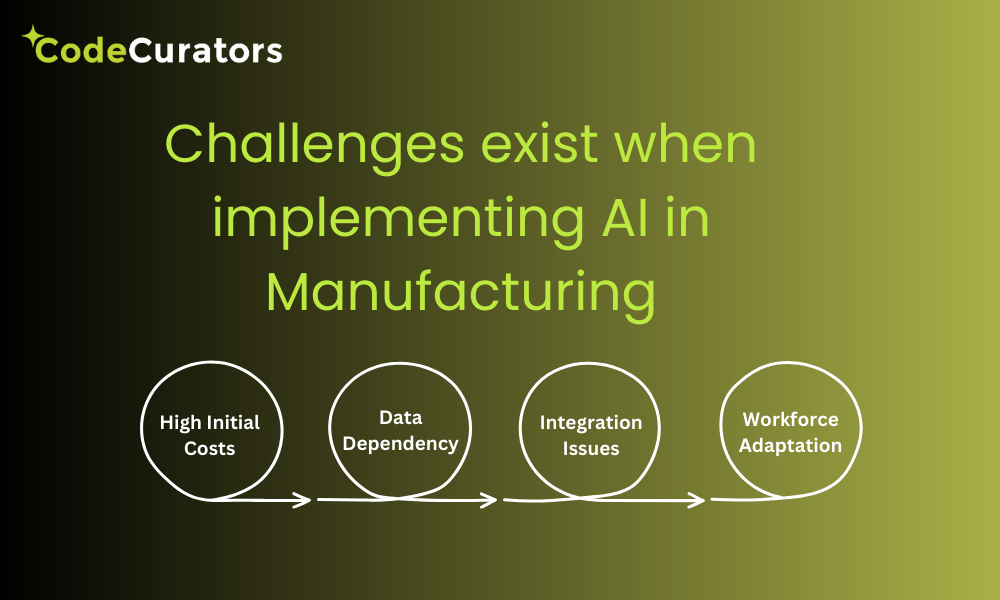

What challenges exist when implementing AI in manufacturing?

While the benefits are significant, implementing AI is not without challenges:

1. High initial costs:

Both complex AI and the environments that support such systems are not inexpensive. The high initial cost is one of the chief concerns many manufacturing companies feel.

2. Data dependency:

AI has more dependence on quality data and needs a significant quantity of data for the workspace. To provide the wrong recommendations or forecast, you need to feed the algorithm with inconsistent or inferior data quality.

3. Integration issues:

Technologies based on AI can sometimes integrate with existing legacy systems with some level of difficulty and with much necessary reorganization.

4. Workforce adaptation:

Workers may need retraining to collaborate with artificial intelligence systems, and change may face opposition.

To overcome these hurdles, manufacturers should consider phased AI implementation, invest in employee training, and prioritize data management.

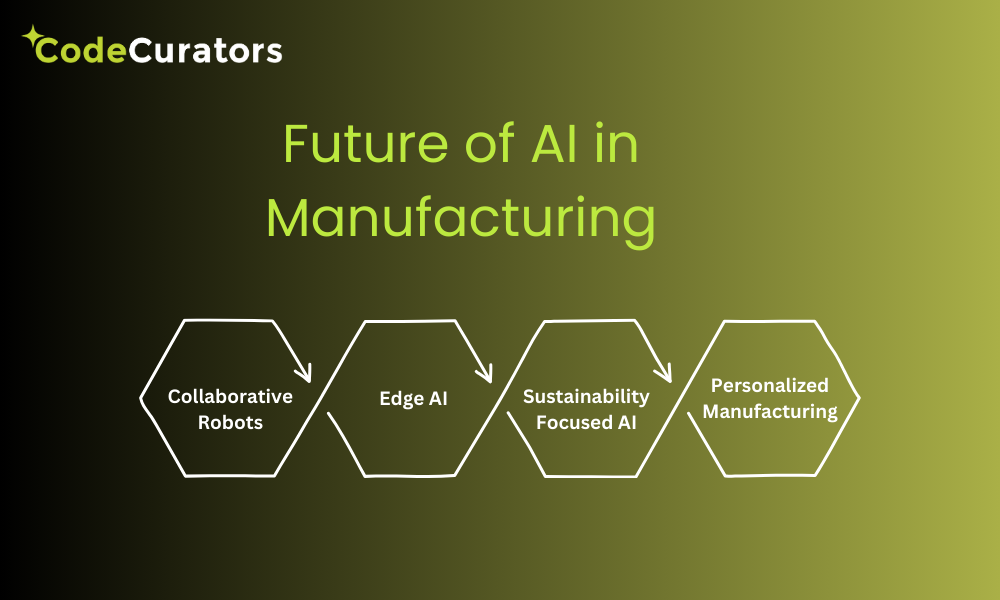

What Is the Future of AI in Manufacturing?

The future of manufacturing will likely be defined by even deeper AI integration. Emerging trends include:

1. Collaborative robots (Cobots):

These robots will complement man in that they bring into the equation, the mechanical accuracy of a robot and the flexibility of man.

2. Edge AI:

AI processing at the edges of networks will be a boon for decision making mechanisms because it will help in the localization of data processing.

3. Sustainability-Focused AI:

AI will be responsible for further contributing to the right utilization of energy so as to minimize wastage in the manufacturing firms to meet environmental objectives.

4. Personalized manufacturing:

AI will improve the production capacity of manufactures so as to meet the consumers’ demand for personalisation.As AI technologies evolve, their integration with other innovations like IoT, 5G, and blockchain will further revolutionize the manufacturing sector, making it more efficient, innovative, and sustainable.

Conclusion

Artificial intelligence in manufacturing has become instrumental in solving some of the oldest problems facing the industry while providing new opportunities for expansion. From improving speed and accuracy to transforming growth trajectories and enabling more sustainable practices, AI offers endless possibilities. However, despite barriers such as high costs and integration challenges, the advantages significantly outweigh the disadvantages.

The automotive sector, in particular, is gearing up to become smarter, more flexible, and better prepared for the global market as manufacturers increasingly adopt AI technology. For organizations aiming to remain at the forefront of the competitive landscape, leveraging AI in Manufacturing is no longer a luxury but an absolute necessity.

We can assist you if you are prepared to use AI to improve your manufacturing processes. For a consultation on how advanced AI technologies may boost your business’s operations, increase productivity, and promote long-term success, get in touch with us. Together, we can overcome obstacles, take advantage of fresh chances, and establish your company as a leader in the field. Are you prepared to welcome the AI-powered manufacturing of the future? Contact us right now, and together, let us make it happen.